Last night was the January beer meeting night at ‘Arry’s. We had 23 members show up and 17 guests, many of whom are going to join the club. And this doesn’t even include the two people that I’d invited. The food was plentiful as was the beer, and today I’m paying. I’m not even going to step onto the scale for a few days in hopes that the gaining trend will reverse it’s elf. Got to stop eating at every op.

An example was the Road Trip that many of us took the other night to Bull & Bones restaurant and brewpub in Blacksburg VA the other night. Oh, yeah.. you gotta go there…

But, the reason for the road trip was to celebrate one of our own ‘s “Izvinite Babushka” Russian Imperial Stout winning of the annual Brew Do in Blacksburg and having his winning beer, brewed by B&B. He assisted the head brewer in brewing this interesting beer. They have already sold a barrel of the stuff, it is mighty popular. As a matter of fact, people from our club won top honors in all four categories of beers that were contested at Brew Do, but this was Justin’s day. A good time was had by all, and much good food & beer was consumed! Oh, I was miserable; not from drinking too much, I only had two IPAs and one snifter of the Imperial Stout (not one of my favorite styles), but from eating the Pork Barbecue Platter and a few hot wings that were offered. And DAMN they were hot… the sneaky kind of hot.. the kind that melts the skin off of your lips a few minutes after eating the little darlin’s.

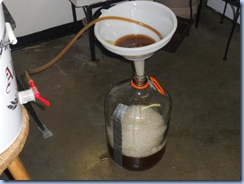

Now, I have to plan on the next beer that I’ll brew, maybe another ESB, but one of the next will be an Oktöberfest, now that I can lager again, in my new chest freezer. More on that as it happens!